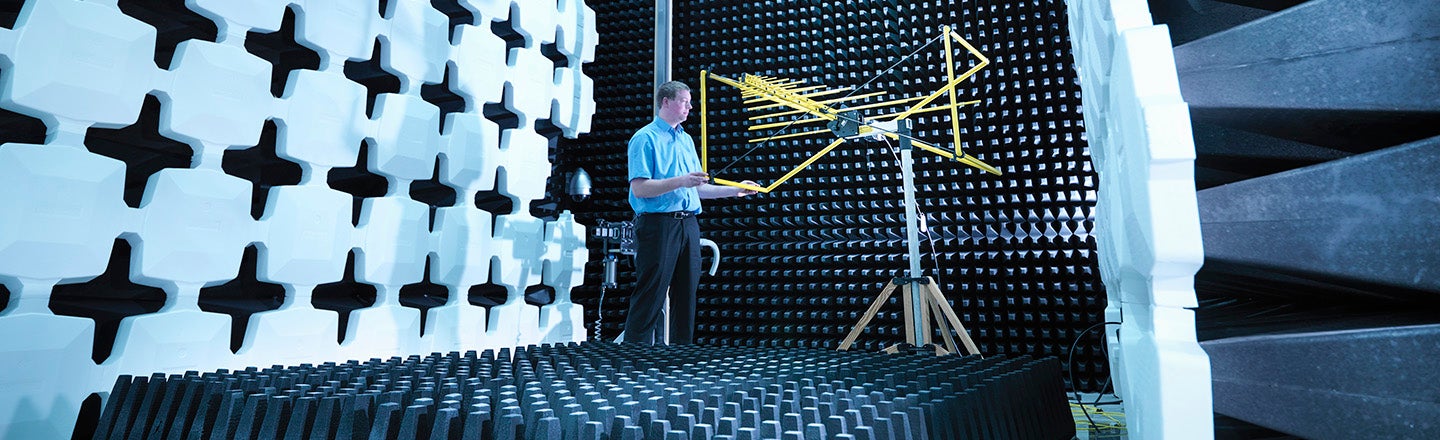

3m pre-scan Immunity/Emissions semi-anechoic chambers are designed to perform ANSI C63.4/CISPR 16-1-4 and IEC 61000-4-3 compliant radiated immunity and emissions measurements. When using this chamber for ANSI C63.4 pre-compliant radiated emissions pre-scan measurements there’s a limited scan height.

Pre-Scan Emissions/Immunity Chambers

C-LCI offers (2) different pre-scan models; our smaller version measures 22’L x 10’W x 10’H and comes only ferrite lined. With ferrite only the chamber can test from 26MHz-1GHz. Our larger model comes with a combination of ferrite tile plus Cuming Microwave’s C-RAM HFP hybrid absorbers; absorbers specifically tuned to receive the hand off and pick up frequencies ≥ ~1GHz.

Frequency ranges for these pre-scan chambers are 26 MHz to 40 GHz (radiated immunity) and 30 MHz to 40 GHz (radiated emission).

Tech Specifications

Clear Dimensions* : 12′-0″ (W) x 24′-0″ (L) x 11′-0″ (H)

Operating Frequency Range : 26MHz-18 GHz

Anechoic Absorber Type : Optimized Dielectric-Ferrite/Pyramidal Hybrid

Shielding Effectiveness : 100 dB, Electric, Planewave, Microwave

Radiated Immunity Test Capability : YES

IEC 1000-4-3 Compliance : YES

Uniform Field Area : 1.5m x 1.5m

Field Uniformity Performance : -0 +6dB

Radiated Emissions Test Capability : YES / Prescan w/ limited scan height

ANSI C63.4 Compliance : NO (Pre-Scans for Site Attenuation Correlation)

Site Attenuation Performance : + or – 4dB < 200 MHz, + or – 6 dB 30 MHz – 200 MHz

Test Volume Size : Meter Diameter

Maximum Scan Height : 2 meters

* Inside Clear Dimensions are calculated to the face of the shielded enclosure.

Installation/Accessories

Prescan Emissions/Immunity Chamber DESIGN:

- Chamber analysis/optimization

- Chamber design & structural engineering

- Hybrid absorber optimization

- Design reviews

- Submittal drawings

- As-built drawings (optional)

SHIELDED ENCLOSURE-

- RF shielded enclosure

- Free standing design – structural support system

- Modular wood-core panel construction

- Waveguide ventilation panels – (2) 12″ x 12″

- Bulkhead connector panels – (1) 12″ x 18″

- RF shielded lighting system – Lighting Options

- RF shielded door – (1) 3′ x 7′ Single leaf access door, low threshold

- Powerline filters – (2) 2×30 amp

- Conduit, one switch, and two receptacles

- Electrical Distribution

- Shielding effectiveness testing per IEEE-299 and MIL-STD 285 at 1 GHz

ANECHOIC ABSORBER

- Optimized proprietary dielectric-ferrite/pyramidal absorber

- Quality control of absorber manufacture

- Quality control of installation

- Modular ferrite floor absorber

TESTING (Optional)

- Field uniformity testing – IEC 10000-4-3 compliance

- Normalized Site Attenuation testing for prescan emissions – ANSI C63-4 (Limited Height)

- Detailed test plans and reports

EQUIPMENT PACKAGE (Optional)

- 1.2 Meter Diameter Turntable, surface mount, low profile. 800 lb. running load

- Antenna Tower, scans from 1-2 meters, pneumatic polarization standard w/fiber optic interface

- Dual Channel System Controller, Variable speed control, fully IEEE 488.2 compatible, as well as with industry standard automation software.

Warranty –

- 1 year warranty on materials and workmanship

- 3 year warranty on absorber material, under normal conditions

- 5 year warranty on RF shielding effectiveness