Expanding Technology

Our expanded material Our expanded materials demonstrates exceptional performance because we are able to control our processes to tighter tolerances and manufacture a high-quality, repeatable product.

Expanding Materials for Evolving Applications

Today, materials must advance to meet the needs of emerging engineering applications. Bridge the gap between your prototype and end-use product with precision expanded materials. DEXMET® MICROGRID® metal foils and POLYGRID® polymers are used in batteries, electronics, aircraft, wind energy, medical, packaging, filters, fuel cells, electrolyzer, heating elements, food & drug packaging, automotive, and wherever mesh and perforated foils, metals and plastics with high precision characteristics are required.

How Expanded Materials are Made

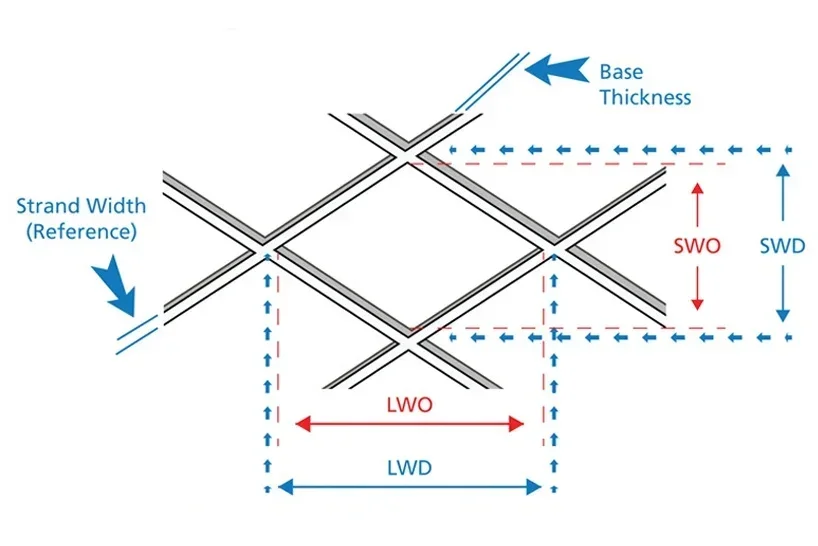

Expanded metal and polymer is made by a process of slit and stretch. A precision die slits and stretches the material in a single operation. The material is then processed through a set of rollers which adjusts the final thickness. The shape, form and number of openings are dictated by the particular tool used (See Die Chart for discussion on available dies).

Long Way of the Diamond (LWD)

Measured from the center of the node to the center of the adjacent node. This dimension is built into the tool and is always parallel to the width of the coil and corresponds with the diamond dimension

Short Way of the Diamond (SWD)

The length of the short axis way of the diamond, measured from the center of the node to the center of the node. For each fixed LWD dimension there is a SWD range.

Strand Width

The strand width is the amount of metal slit from the parent metal in forming the mesh. The strand thickness is directly proportional to the feed rate of the material into the machine.