When it comes to cookware and bakeware, there is no shortage of options on the market with products in every size, color and style. Most cooks, from novices to culinary connoisseurs, base their purchasing decisions on finding the best balance of price and performance to fit their needs.

Putting Non-stick Coatings Performance to the Test

It's common for manufacturers to have a portfolio of cookware at a variety of price points. Whether a product is considered economy or premium depends on how they are constructed, including the quality of materials used, and how well they perform on factors like food release, scratch resistance, even heating, cleaning and durability based on product testing. But testing methodologies and standards vary widely.

For most industries, testing standards are set by ASTM International, formerly known as the American Society for Testing and Material, but ASTM standards do not apply to niche products like non-stick coatings.

PPG is a member of the Consumer Bakeware Alliance that does publish engineering and testing standards, but they are not uniformly used across the industry, leaving testing to the discretion of individual manufacturers and coatings makers.

Setting the Testing Standards for Non-stick Coatings

Every cookware manufacturer and coatings company have their own sets of tests. PPG uses a specific round of rigorous tests for non-stick coatings, along with customer-specific testing.

"Our customers trust us to conduct testing on their behalf," explained Kurt Mecray, a 30-year industry veteran who is heavily involved in testing of PPG's cookware and bakeware coatings as a technical manager. "As a leader in testing, we often recommend our specific methods first, but of course, are open to other test methods based on customer preferences."

Perfecting the Test

Today, PPG's non-stick testing methodologies are among the most rigorous in the industry. They were first developed by Whitford Worldwide, a company acquired by PPG in 2019 that specialized in low-friction and non-stick coatings. Kurt was one of the key employees who came to PPG through the acquisition.

Whitford's extensive and arduous testing methods helped to establish the company as a global leader in non-stick coatings for housewares.

The testing work for PPG's kitchen and industrial bakeware business is done at one of seven labs around the world: two based in the U.S. with others in South America, Asia and Europe.

PPG's testing methods are engineered to ensure that PPG coatings not only maintain their non-stick performance for an extended period, but also to measure how well they fare against other leading brands, comparative data that is immensely helpful to both PPG and its customers.

This commitment to the most robust methods has resulted in a test matrix for housewares that is highly regarded as the standard across the industry. In fact, it is common for independent labs to refer to PPG tests in third party documentation.

Non-stick Coatings Performance Tests

For non-stick coatings for consumer and industrial cookware, abrasion, thermal shock, chemical-resistance and adhesion testing are common. The specific testing regimen used, however, depends on whether the non-stick coating is formulated with sol-gel ceramic technology or polytetrafluoroethylene (PTFE), one of the most widely used PFAS compounds.

Sol-Gel Ceramic Non-stick Testing

PPG's newest non-stick coatings are based on sol-gel technologies that are made without intentionally added PFAS compounds.

Unlike traditional PTFE-based non-stick coatings, wear and abrasions are not a common cause of coatings failure since sol-gel formulations are extremely hard and the coating doesn’t easily wear or scratch with use.

Because the solutions use silicone-based oil as a release agent that is not bonded with the coating beneath it, the biggest threats to this two-coat system are high heat and chemicals that deplete the oil, resulting in loss of non-stick performance.

Dishwashers and excessive heat at 600 ° F (316 ° C) for an extended period are detrimental and will shorten the working life of the pan.

To help ensure that PPG's sol-gel coatings perform at the highest level, chemical testing is conducted by running the pans through a simulated dishwasher to see how many cycles the coating can endure and still retain the silicone-release properties.

The second method is the thermal shock test where the pan is heated to 600 ° F (316 ° C) for one hour, plunged into cold water and the immediately used for cooking. The extreme conditions are repeated dozens of times until the coating fails.

The coatings undergo additional tests specific to abrasion resistance, corrosion and performance with acidic foods and demanding use.

PPG FUSION PRO holds up under extreme conditions

PPG's FUSION ® Pro sol-gel ceramic non-stick coating stands up to high heat with a continuous use temperature of 550 ° F (288 ° C), features a hard, durable non-stick surface that's been tested to last more than twice as long as comparable sol-gel coatings, and offers excellent performance in both dishwashing and thermal shock testing. Like all sol-gel ceramic coatings, it’s also made without intentionally added PFAS compounds.

PTFE Non-stick Testing

Unlike newer generations of non-stick sol-gel ceramic formulations, PTFE coatings like PPG's ETERNA® and ECLIPSE® brands, can endure endless thermal cycling tests without loss of non-stick performance.

Their most common cause of failures, scratches and abrasions is heavy use, metal utensils and harsh scrubbing that wears down the non-stick coating and exposes the metal substrate.

While PTFE-based non-stick coatings are highly durable, they are subject to increasing regulations and efforts to limit their use because of their inability to break down in the environment over time.

The primary testing methods for PTFE coatings are the Mechanical Scratch Test (MST), the dry egg test, and the LGA shaker test, a method common in Europe.

The hardest, most extreme test for PTFE non-stick coating cookware is the mechanical scratch test, commonly referred to as the happy flower test because of the testing pattern.

During this process, a coated item is filled with hot oil, maintained at 300 ° F (149 ° C), and then a ballpoint pen is scribed across the surface with a 300-gram point load for two hours in a pattern and process similar to the spirograph many of us played with as children. The item is then rated on a scale from 0 to 9 for wear, exposure of bare metal and fraying.

Next is the LGA shaker test where the pan is divided into sections and filled with a variety of mixtures and items like chrome-steel balls, water and abrasive minerals like corundum. The pan is shaken and spun at high RPMs and assessed every 15 minutes. Finally, the non-stick performance is tested with food items like pancakes and burnt milk.

The classic dry-egg test is the standard for non-stick coatings where single eggs are added to a preheated pan without oil and cooked for 2.5 minutes. The effort to release the egg is measured on a 5 to 1 scale with 5 being easy to remove. The test is repeated until the egg no longer lifts easily from the pan, indicating diminishing non-stick performance.

Testing of PPG's ETERNA non-stick coating

While five rounds of the dry-egg test is considered sufficient for most manufacturers, PPG's PTFE non-stick coatings sold under the PPG ETERNA® brand have lasted hundreds of times before failure, outperforming the best known brand and closest competitor's non-stick system.

Available in a two-coat or three-coat system, Eterna cookware coatings provide outstanding long-term non-stick properties for gourmet housewares products.

Beyond quick release, the system offers an extremely smooth, higher gloss than most other PTFE non-stick coatings.

PPG Non-stick Solutions

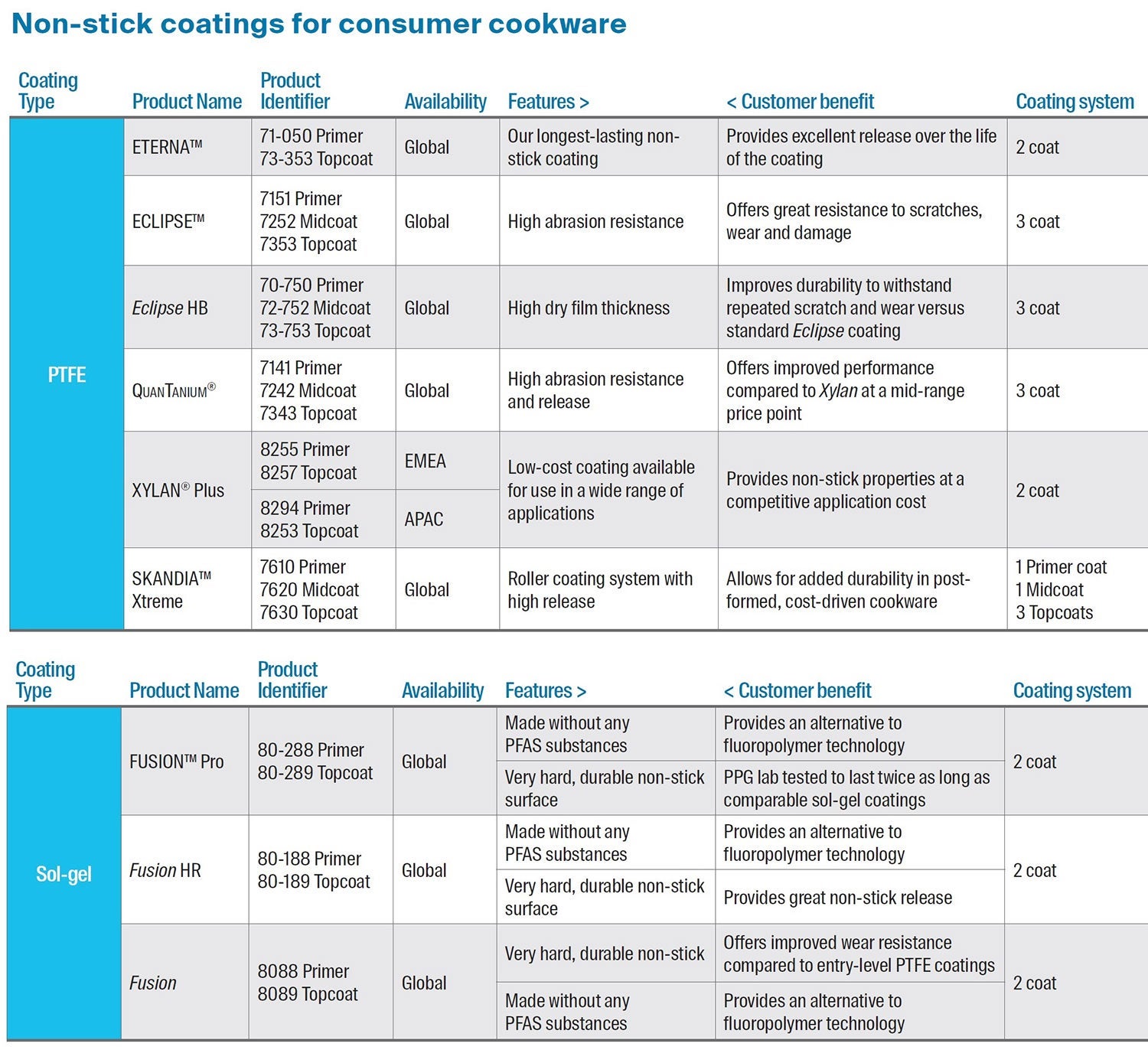

Our comprehensive line of non-stick coatings is available in a range of options for consumer cookware applications. They offer the unique combination of excellent non-stick performance and durability and are available in both PTFE and sol-gel ceramic platforms.

PPG non-stick coatings can be developed to meet specific color, texture and visual effects, all while remaining food-contact compliant.